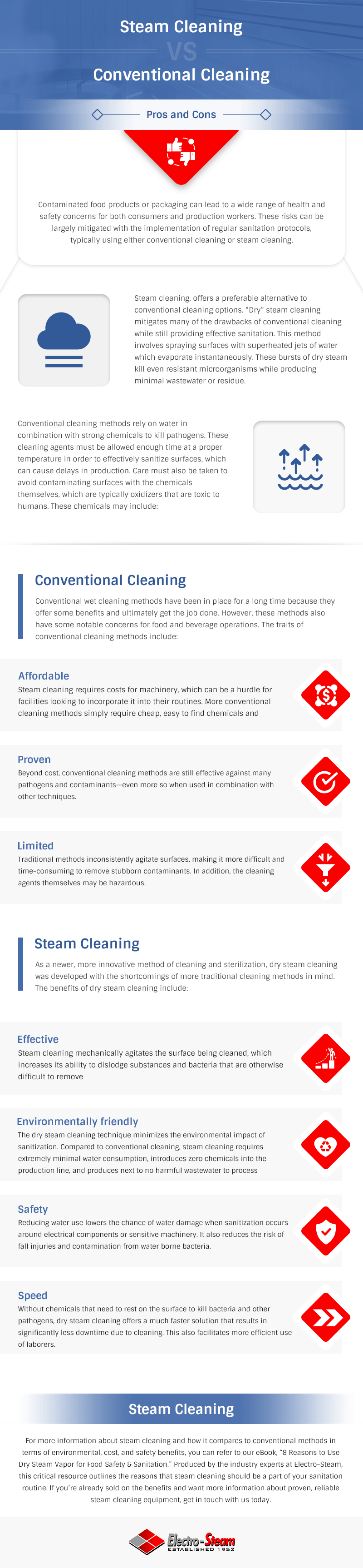

Pathogenic bacteria can survive on stainless steel at room temperature for prolonged periods of time, meaning that a failure to properly sanitize surfaces in food and beverage applications can lead to harmful cross-contamination. Contaminated food products or packaging can lead to a wide range of health and safety concerns for both consumers and production workers. These risks can be largely mitigated with the implementation of regular sanitation protocols, typically using either conventional cleaning or steam cleaning.

Conventional cleaning methods rely on water in combination with strong chemicals to kill pathogens. These cleaning agents must be allowed enough time at a proper temperature in order to effectively sanitize surfaces, which can cause delays in production. Care must also be taken to avoid contaminating surfaces with the chemicals themselves, which are typically oxidizers that are toxic to humans. These chemicals may include:

- Hypochlorites

- Chlorine dioxide

- Iodophors

- Peroxyacetic acid

- Quaternary ammonium compounds

Steam cleaning, on the other hand, offers a preferable alternative to conventional cleaning options. “Dry” steam cleaning mitigates many of the drawbacks of conventional cleaning while still providing effective sanitation. This method involves spraying surfaces with superheated jets of water which evaporate instantaneously. These bursts of dry steam kill even resistant microorganisms while producing minimal wastewater or residue.

Conventional Cleaning

Conventional wet cleaning methods have been in place for a long time because they offer some benefits and ultimately get the job done. However, these methods also have some notable concerns for food and beverage operations. The traits of conventional cleaning methods include:

Affordable

Steam cleaning requires costs for machinery, which can be a hurdle for facilities looking to incorporate it into their routines. More conventional cleaning methods simply require cheap, easy to find chemicals and cleaning tools.

Proven

Beyond cost, conventional cleaning methods are still effective against many pathogens and contaminants—even more so when used in combination with other techniques. However, conventional cleaning may not be fully effective against all hazardous materials. For instance, many pathogens have evolved biofilms which protect them from chemical penetration.

Limited

Traditional methods inconsistently agitate surfaces, making it more difficult and time-consuming to remove stubborn contaminants. In addition, the cleaning agents themselves may be hazardous. Conventional cleaning methods increase the risk of chemical cross-contamination, which can be harmful to workers and consumers.

Steam Cleaning

As a newer, more innovative method of cleaning and sterilization, dry steam cleaning was developed with the shortcomings of more traditional cleaning methods in mind. The benefits of dry steam cleaning include:

Effective

Steam cleaning mechanically agitates the surface being cleaned, which increases its ability to dislodge substances and bacteria that are otherwise difficult to remove. What’s more, the process involves extremely high temperatures that can penetrate the protective biofilms of microorganisms, killing pathogens that are resistant to cleaning chemicals and breaking their bond with the surface.

Environmentally friendly

The dry steam cleaning technique minimizes the environmental impact of sanitization. Compared to conventional cleaning, steam cleaning requires extremely minimal water consumption, introduces zero chemicals into the production line, and produces next to no harmful wastewater to process. This makes the practice especially attractive to companies that want to highlight their commitment to sustainable practices.

Safety

Reducing water use lowers the chance of water damage when sanitization occurs around electrical components or sensitive machinery. It also reduces the risk of fall injuries and contamination from water borne bacteria.

Speed

Without chemicals that need to rest on the surface to kill bacteria and other pathogens, dry steam cleaning offers a much faster solution that results in significantly less downtime due to cleaning. This also facilitates more efficient use of laborers.

Although a highly safe and efficient option, steam cleaning is not without its limitations. Because of the equipment involved, steam cleaning necessarily introduces a requirement for additional maintenance and a larger initial investment.

Making the Decision

For more information about steam cleaning and how it compares to conventional methods in terms of environmental, cost, and safety benefits, you can refer to our eBook, “8 Reasons to Use Dry Steam Vapor for Food Safety & Sanitation.” Produced by the industry experts at Electro-Steam, this critical resource outlines the reasons that steam cleaning should be a part of your sanitation routine.

If you’re already sold on the benefits and want more information about proven, reliable steam cleaning equipment, get in touch with us today.